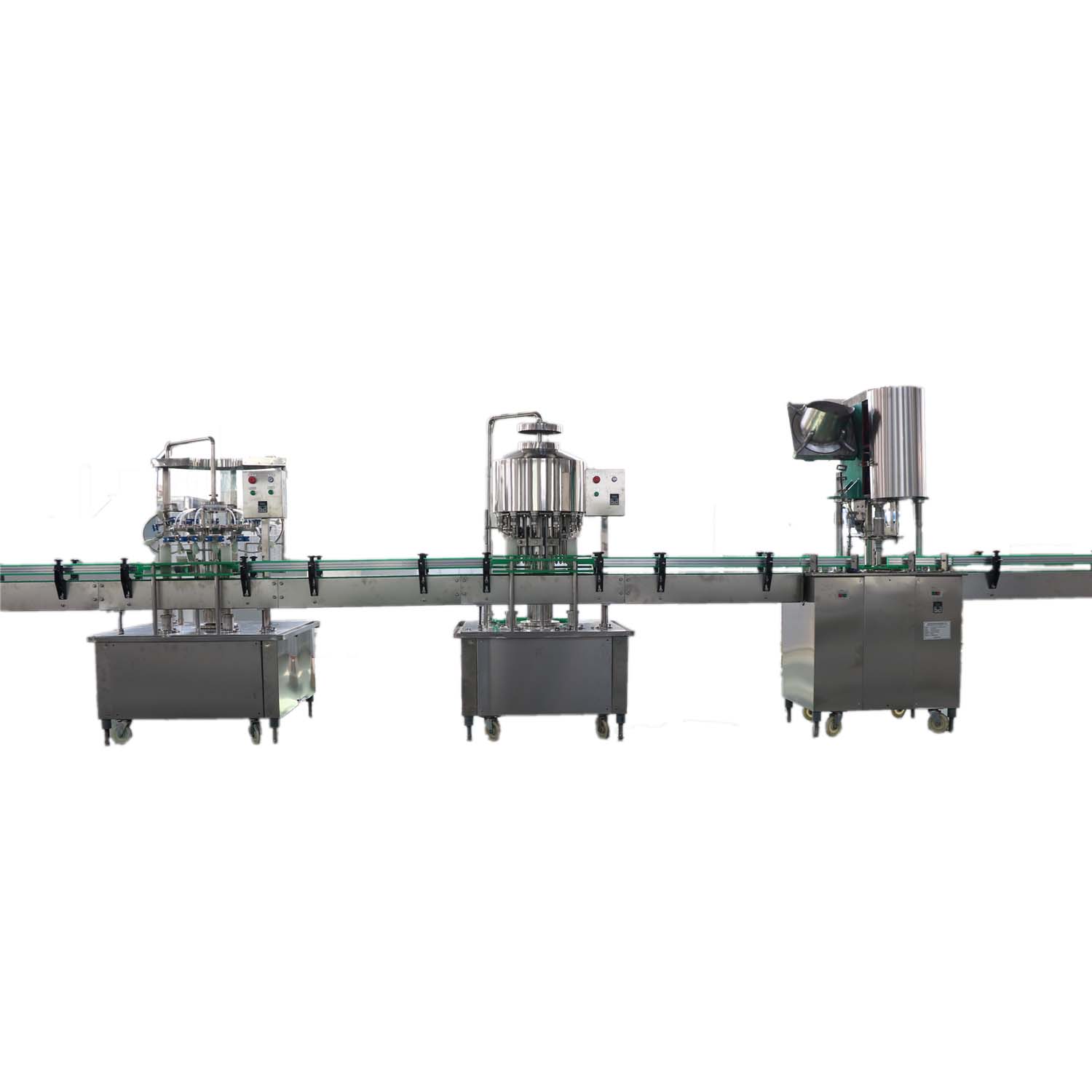

2000bph water filling line For plastic bottle from 300ml to 1500ml

1. auto plastic bottle washing machine

It adopts continuously spraying and washing method. It has high efficiency and good washing result. The equipment is mainly used in cleaning the plastic bottles of mineral water, pure water. It's perfect equipment in the production line of beverage industry.

Main technological data:

Model | VACGF2000-1 |

Washing heads | 12 |

Capacity | 1000-2000BPH(0.5L) |

Bottle diameter | Φ55-Φ100 |

Bottle height | 100-320mm |

Motor power | 1.12kw |

Dimension(mm) | 1200*1000*1800 |

Weight | 448kg |

2. Auto plastic bottle Water filling machine

The filler is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It's mainly used for filling water . It's advanced in construction, steady in performance, safe in operation, easy in maintenance, high in production efficiency, and the speed can be regulated infinitively. The filler is the ideal choice for drink factories of small and middle size.

Technological specifications

bottling heads: | 12 |

Bottle body outer diameter | Φ55-Φ100mm |

Bottle height: | 100-310mm |

capacity: | 2000 BPH |

Filling pressure: | 0.2-0.3Mpa |

Power: | 1.1kw |

weight: | 432kg |

dimension (LXWXH): | 1100*1050*1800mm |

3.Automatic screw capping machine

The machine is widely used for sealing kinds of plastic bottles of gas containing drink or no gas drink. It has the advantages of reasonable mechanical structure, stable in moving, good in feature, easy operation and maintenance, widely used.

Main technological data:

Capping heads: | 1 |

Cap type: | Plastic screw cap |

capacity: | 2000 BPH |

Bottle height: | 100-310mm |

Bottle dia.: | Φ50-Φ100 |

Power: | 0.9kw |

weight: | 284kg |

dimension (LXWXH): | 900*800*1900mm |

automatic sleeve labeling machine

semi-automatic film wrapping shrinking machine

Washing filling and capping machine connect by convey:

video showing