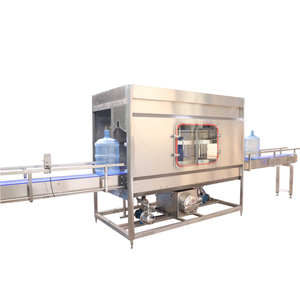

Automatic label cutting and cover pulling machine

This equipment is a newly designed centralized automatic label cutting and cap pulling equipment for 5 gallon buckets. The main material of the equipment is high quality stainless steel. Simple structure. The working action is controlled by PLC programming. Touch screen operation. Safe and reliable, high degree of automation, is the 5 gallon drinking water enterprise labor - saving ideal equipment.

The working process

The recovered bucket is manually placed on the conveyor belt, and the conveyor belt brings the bucket into the working area of the label cutting and cap pulling machine. After the sensor checks the bucket, the cutting label head is started, and the cutting label head slides up and down on the barrel mouth to effectively remove the shrinking film of the barrel mouth. After the film is removed, the waste film is blown into the container of the recycling film by air. Then pull the cap downward movement, pull out the lid on the bucket, and blow into the recycling container. After the work is completed, the bucket will be transported to the next work area by conveyor belt.

Main parameters of automatic de-capper with label remover .

Model | LCD-1 |

De-capper head | 1 |

Label cut head | 1 |

capacity | 900bph |

power | 4kw,380v,3ph,50hz |

Dimension | 900x700x1800mm |

Air consumption | 800L/Min |

Pressure | 0.6Mpa |

video showing