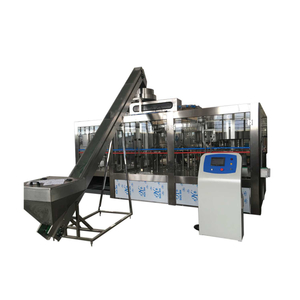

The filling machine is suitable for 5L-15L plastic bottle application water production. Equipment set washing, filling, sealing, forming an integrated equipment. Adopting linear filling technology, it has the advantages of high stability, high degree of automation, simple operation and good safety performance.

The process flow

Empty bottle - conveying - washing bottle/filling/sealing integrated machine (automatic capping/capping/washing)- conveying - lamp inspection - blow-drying machine - labeling machine - laser coding machine - film charter machine - finished water

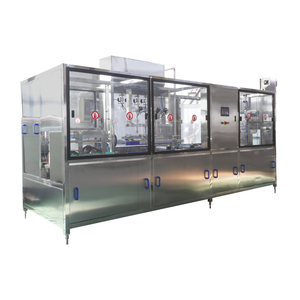

Technical features and description

1. The photoelectric sensor is adopted to detect a certain number of bottles when washing, and the working turnover of the clamping cylinder at the mouth of the bottle is 180°. The washing time and drip-drying time of pure water are adjustable

2. Enter the filling part after washing, and use the open-mouth filling method

3. After filling, enter the capping position and use magnetic capping. If there are bottles, no capping will be put.

PLC control, touch screen operation.

Main models

model | XGF4-4-1 | XGF5-5-1 | XGF6-6-1 | XGF8-8-2 |

Washing heads | 4 | 5 | 6 | 8 |

Filling heads | 4 | 5 | 6 | 8 |

Sealing heads | 1 | 1 | 1 | 2 |

capacity | 400bph | 500bph | 600bph | 800bph |

Bottle | 5L-15L | 5L-15L | 5L-15L | 5L-15L |